“Ship seals” can refer to several different types of seals used in the maritime industry. These seals serve various functions and are essential for the safety, security, and functionality of ships. Here are some common types of ship seals:

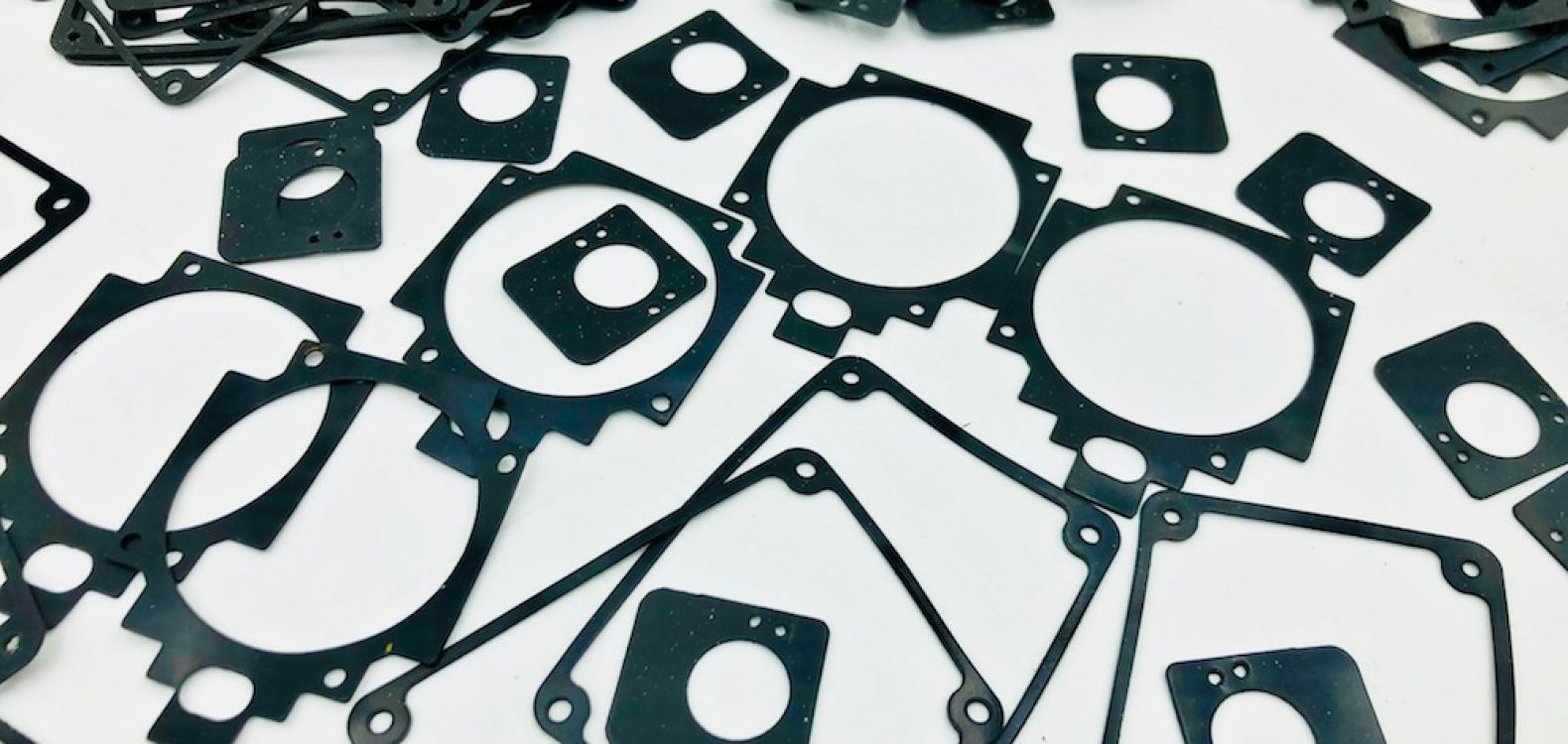

- Hull Seals: Hull seals are designed to maintain the watertight integrity of a ship’s hull, preventing water from entering the vessel and ensuring buoyancy. Hull seals include gaskets, seals around hatches and doors, and other components that seal the ship’s interior from the external environment.

- Shaft Seals: Shaft seals, also known as stern tube seals or propeller shaft seals, are used to prevent water from entering the ship’s hull through the opening where the propeller shaft passes through the hull. These seals are critical for preventing water ingress and maintaining the ship’s stability.

- Cargo Hatch Seals: Cargo hatch seals are used on cargo ships to create a watertight and airtight seal around the cargo hatches. These seals prevent seawater from entering the cargo hold and protect the cargo from damage.

- Porthole Seals: Porthole seals are used to create a watertight seal around portholes or windows on a ship’s hull. They prevent water from entering cabins or other interior spaces while providing visibility.

- Manhole and Access Door Seals: Seals around manholes and access doors ensure that these openings are watertight when closed. This is especially important in areas like engine rooms and cargo holds.

- Expansion Joint Seals: Ships often have expansion joints in their structures to accommodate flexing and movement. Expansion joint seals help maintain the integrity of these joints while preventing water ingress.

- Lifeboat and Liferaft Seals: Seals on lifeboat and liferaft hatches are crucial to ensure that these safety equipment items remain airtight and buoyant in emergency situations.

- Soundproofing and Acoustic Seals: In passenger ships or naval vessels, soundproofing seals are used to reduce noise transmission between compartments and provide acoustic insulation.

- Hydraulic and Pneumatic Seals: Ships use hydraulic and pneumatic systems for various functions, and seals are used within these systems to prevent fluid or air leakage.

- Refrigeration and HVAC Seals: Seals in refrigeration and HVAC (Heating, Ventilation, and Air Conditioning) systems help maintain temperature control in ship compartments.

The materials used for ship seals vary depending on the specific application, but they often include rubber, elastomers, and other resilient materials capable of withstanding the harsh marine environment. Proper installation and maintenance of ship seals are crucial for the safety and performance of vessels at sea.

Ship seals are subject to inspection and maintenance as part of routine ship servicing to ensure they remain in good condition and continue to perform their intended functions effectively. Damaged or deteriorated seals must be replaced promptly to prevent potential leaks, environmental damage, and safety risks.