Aluminum rubber seals, also known as aluminum-rubber gaskets or aluminum-rubber seals, are sealing components that combine aluminum and rubber materials to provide effective sealing solutions in various applications. These seals are designed to create a barrier against the ingress of moisture, dust, contaminants, and other environmental factors while maintaining flexibility and durability. Here are some key aspects of aluminum rubber seals:

Key Features of Aluminum Rubber Seals:

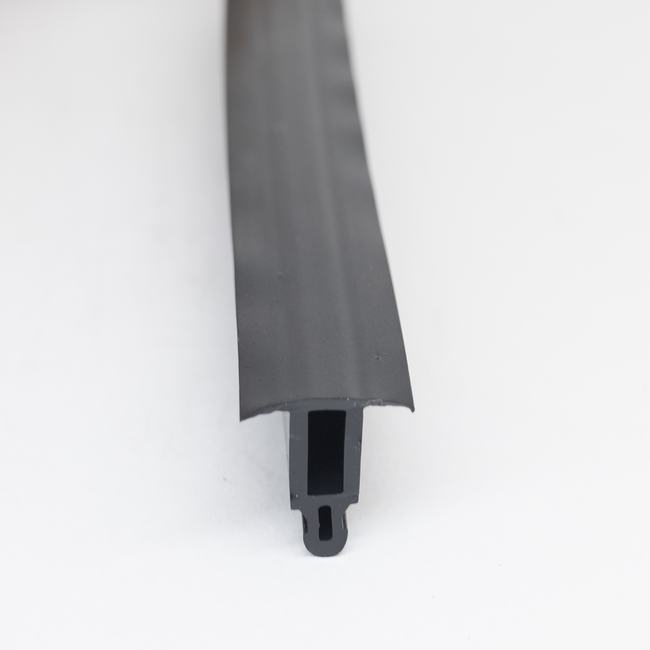

- Material Combination: Aluminum rubber seals typically consist of a core made of aluminum or aluminum alloy and a layer of rubber or elastomeric material on one or both sides. This combination provides the benefits of both materials.

- Sealing Efficiency: Aluminum rubber seals are engineered to provide a high level of sealing efficiency. The rubber layer provides a flexible, compressible seal, while the aluminum core adds rigidity and stability.

- Corrosion Resistance: The aluminum component of these seals is resistant to corrosion, making them suitable for outdoor and harsh environments.

- Chemical Compatibility: The choice of rubber material can be tailored to provide chemical resistance, ensuring compatibility with various fluids and environments.

- Temperature Tolerance: Aluminum rubber seals can handle a wide temperature range, making them suitable for both hot and cold environments.

Applications of Aluminum Rubber Seals:

- Automotive Industry: Aluminum rubber seals are used in various automotive applications, such as engine compartments, doors, windows, and sunroofs, to provide weatherproofing and noise reduction.

- Construction and Building: These seals are employed in architectural applications, including doors, windows, curtain walls, and skylights, to maintain energy efficiency and weather resistance in buildings.

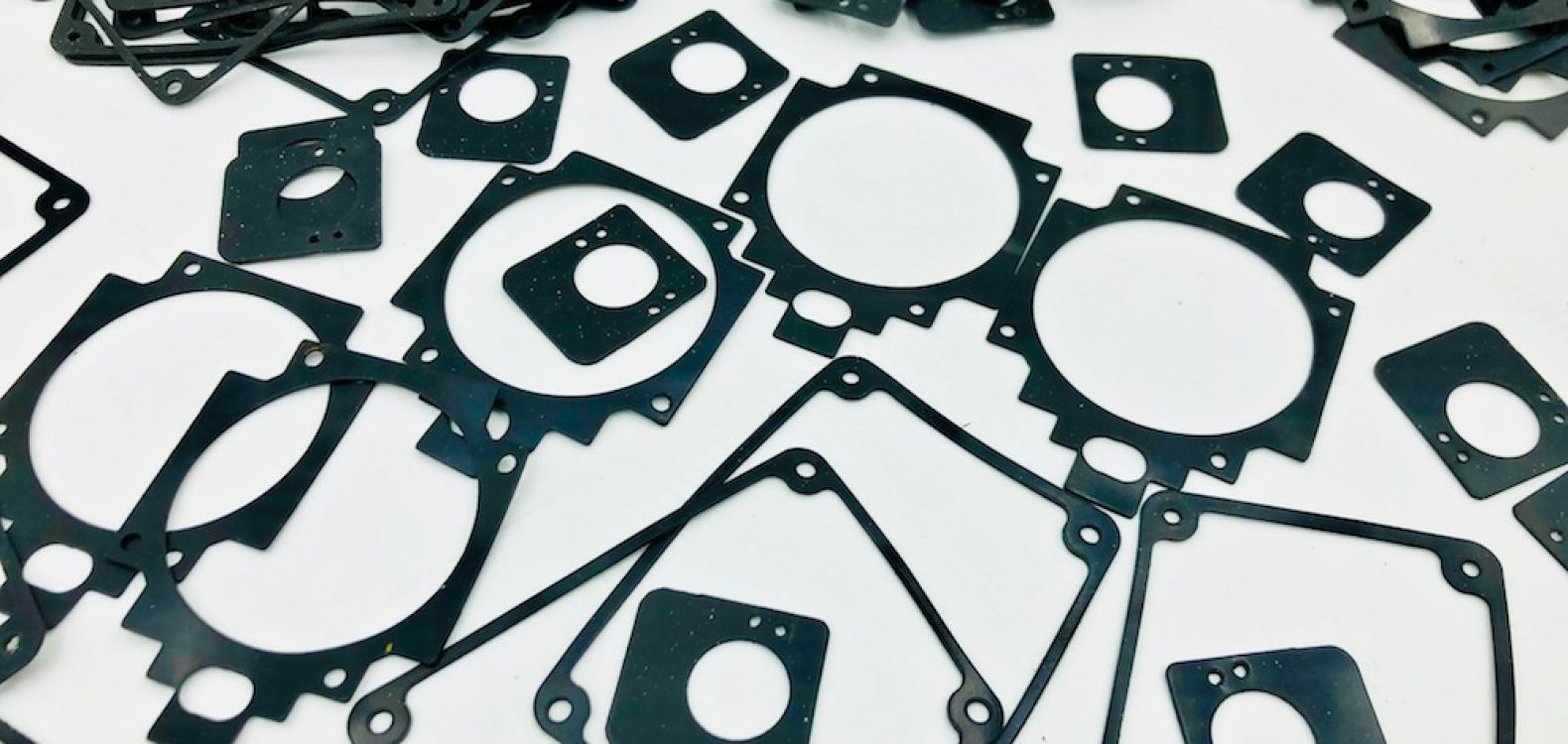

- Electrical and Electronics: Aluminum rubber seals are used in enclosures, control panels, and electronic devices to provide ingress protection against moisture and contaminants.

- Aerospace: In the aerospace industry, these seals can be found in aircraft doors, windows, and access panels, ensuring airtight and secure closures.

- Marine Applications: They are used in marine vessels for sealing hatches, doors, and other access points to prevent water intrusion.

- Industrial Equipment: Aluminum rubber seals are employed in machinery, equipment, and manufacturing processes where environmental sealing is essential to prevent dust, dirt, and moisture from affecting operations.

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, these seals provide insulation and sealing in ductwork, access doors, and ventilation components.

Installation and Maintenance:

Proper installation of aluminum rubber seals is crucial to ensure their effectiveness. This includes correctly aligning and fastening the seals to the mating surfaces, ensuring a secure and complete seal. Periodic inspection and maintenance should be performed to check for wear, damage, or degradation of the rubber component. Replacing damaged seals promptly is essential to maintain their sealing properties and protect the equipment or structure they seal.

The choice of aluminum rubber seals type and material should be based on the specific requirements of the application, including environmental factors, temperature ranges, and chemical exposure. Manufacturers’ guidelines and recommendations should be followed for optimal performance and longevity.