Concrete pipe seals, also known as concrete pipe gaskets or concrete pipe joints, are sealing components used in the construction and installation of concrete pipes. These seals play a critical role in creating watertight, airtight, and secure connections between concrete pipe sections. Concrete pipes are commonly used in various applications, including stormwater drainage systems, wastewater systems, culverts, and more. Here are some key aspects of concrete pipe seals:

Types of Concrete Pipe Seals:

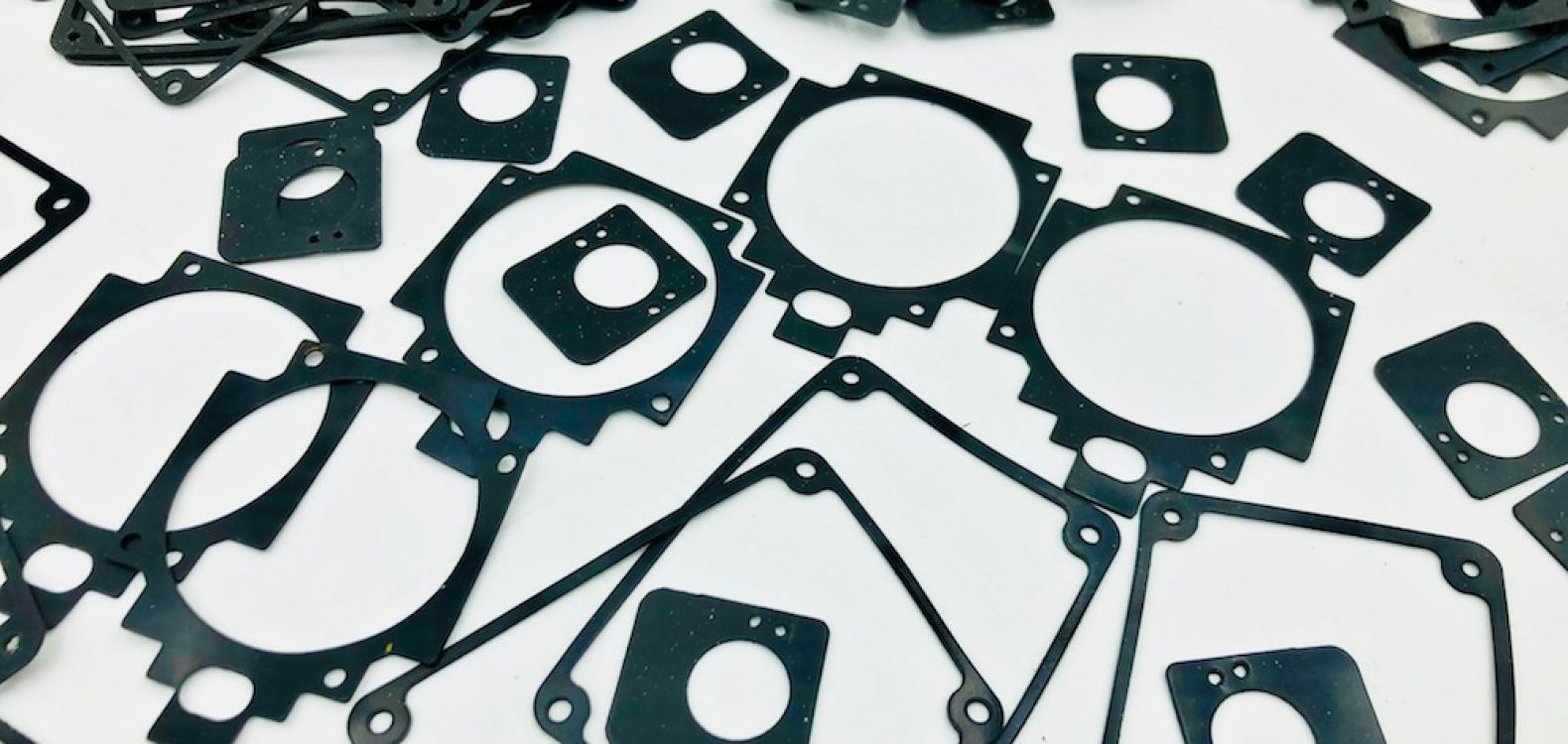

- Rubber Gaskets: Rubber gaskets are the most common type of seal used in concrete pipes. They are typically made of elastomeric materials such as EPDM (Ethylene Propylene Diene Monomer) or neoprene and are designed to create a flexible and watertight seal between concrete pipe sections.

- O-Rings: O-rings are circular seals made from rubber or elastomeric materials. They are used in specially designed grooves or recesses in the pipe ends to create a secure and leak-resistant connection.

- Mastic Seals: Mastic seals consist of a malleable, putty-like material that is applied to the joint between concrete pipes. When compressed, mastic seals conform to the irregularities in the concrete surfaces, creating a tight seal.

Key Features and Functions:

- Watertight Sealing: The primary function of concrete pipe seals is to provide a watertight seal at the joints between pipe sections, preventing the leakage of water or sewage.

- Airtight Sealing: In certain applications, such as sanitary sewer systems, airtight sealing is essential to prevent the escape of foul odors and gases.

- Load Transfer: Concrete pipe seals also help distribute external loads and stresses evenly across the joints, enhancing the structural integrity of the pipeline.

- Chemical Resistance: Depending on the application, concrete pipe seals may be required to resist chemical exposure and provide protection against corrosive substances.

Applications of Concrete Pipe Seals:

- Stormwater Drainage Systems: Concrete pipes are commonly used for stormwater management, and concrete pipe seals ensure that water is efficiently transported and that there are no leaks.

- Sanitary Sewer Systems: In sewage collection systems, concrete pipe seals are critical to prevent the escape of sewage, foul odors, and gases.

- Culverts and Drainage Channels: Concrete culverts and drainage channels use seals to maintain efficient water flow and to prevent erosion.

- Utility Tunnels: In underground utility tunnels, concrete pipe seals help maintain the integrity of water, gas, and utility pipelines.

- Irrigation Systems: Concrete pipes equipped with seals are used in agricultural irrigation systems to transport water efficiently.

Installation and Maintenance:

Proper installation of concrete pipe seals is crucial to ensure a reliable and long-lasting seal. This includes ensuring that the seal is positioned correctly and that the pipe sections are properly aligned before sealing. Regular inspection and maintenance are essential to check for wear, damage, or degradation of the seal material. Damaged or worn seals should be replaced promptly to maintain the integrity of the pipeline system.

The selection of the appropriate concrete pipe seals type and material should be based on the specific requirements of the application, including factors such as pipe diameter, pipe material, pressure, and environmental conditions. Manufacturers’ guidelines and recommendations should be followed for optimal performance and longevity.