Dilatation seals, also known as expansion joints or expansion bellows, are critical components in various engineering and construction applications, designed to accommodate the thermal, structural, and mechanical movements within a system or structure. These seals are specifically engineered to manage the expansion and contraction that occurs due to temperature variations, vibration, or other factors, helping to maintain the integrity of the system while minimizing stress and damage.

The primary purpose of dilatation seals is to provide flexibility and allow for the controlled movement of parts or sections within a system or structure. They are commonly found in industries such as construction, petrochemical, manufacturing, and transportation, and they are crucial for maintaining the safety and functionality of pipelines, bridges, buildings, and other infrastructure.

Here is a more detailed description of dilatation seals:

- Design and Construction:

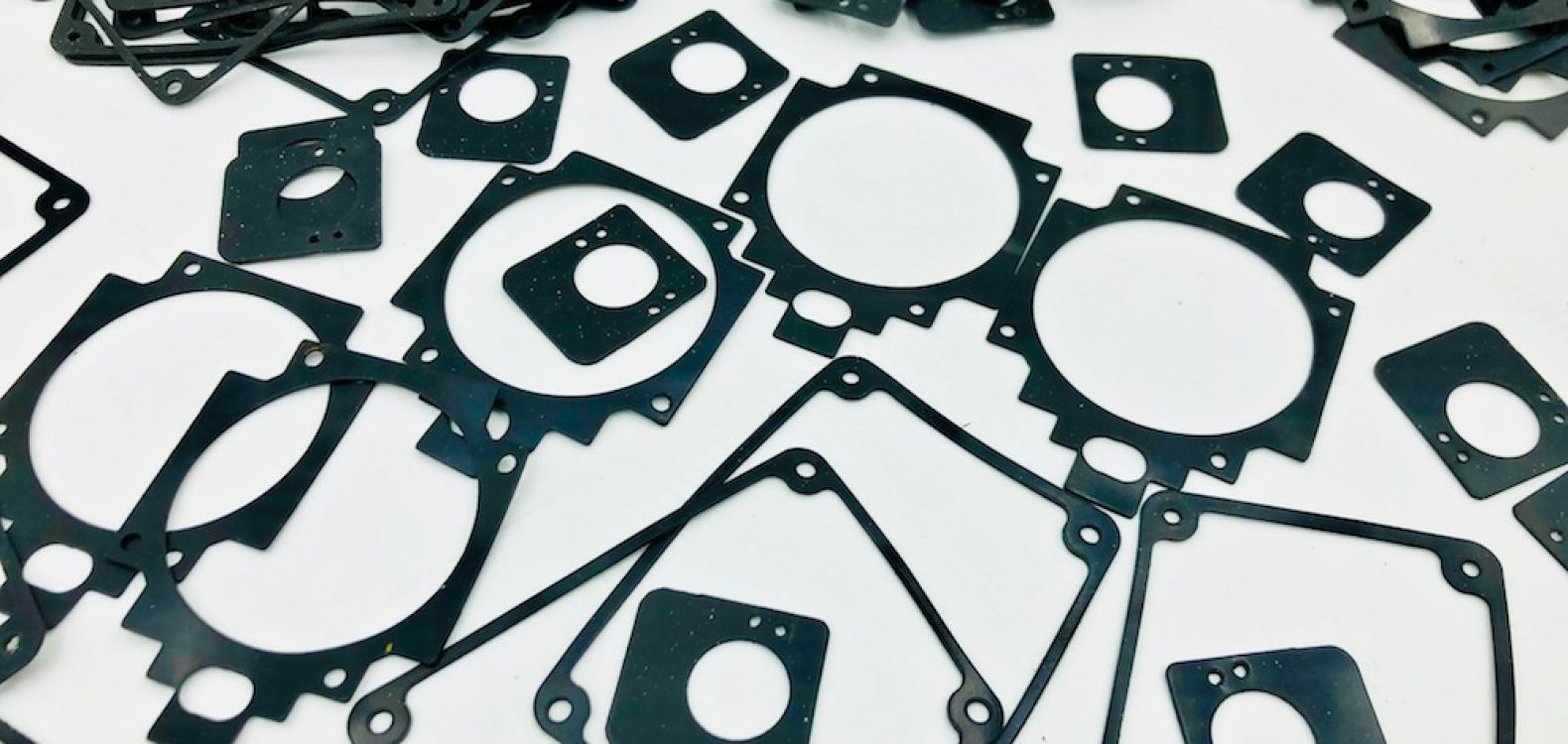

- Dilatation seals are typically made from various materials, depending on the specific application and requirements. These materials can include rubber, metal, fabric, or a combination of these. The choice of material is essential to ensure compatibility with the environment, temperature, and chemical exposure.

- Function:

- They primarily serve as a flexible connection between two adjacent parts or sections of a structure or system. This allows for the controlled movement, expansion, contraction, and vibration while maintaining a tight seal to prevent leakage or structural damage.

- Types of Dilatation Seals:

- There are various types of dilatation seals, each designed to address specific needs. These include:

- Expansion Bellows: These are commonly used in piping systems to absorb thermal expansion and reduce stress on the pipes.

- Control Joints: Found in buildings and structures, they accommodate movements due to settling, temperature fluctuations, or seismic activity.

- Bridge Expansion Joints: These are used in bridges to accommodate the movement of bridge segments caused by temperature variations and traffic loads.

- Metallic Expansion Joints: Designed for high-temperature and high-pressure applications, such as in power plants and industrial facilities.

- Rubber Expansion Joints: Used in various industries to absorb vibrations and dampen noise.

- Installation and Maintenance:

- Proper installation and regular maintenance are essential to ensure the longevity and functionality of dilatation seals. They should be installed correctly to allow for the intended movement and should be inspected and maintained regularly to detect and address any wear or damage.

- Benefits:

- Dilatation seals play a crucial role in maintaining the integrity and safety of structures and systems by preventing leaks, structural damage, and stress. They also contribute to extending the lifespan of equipment and reducing maintenance costs.

- Challenges:

- Dilatation seals can be prone to wear and tear over time, especially in harsh environments or applications with extreme temperatures or pressures. Inadequate maintenance or improper installation can lead to failure and costly repairs.

In conclusion, dilatation seals are essential components in a wide range of industries and applications, ensuring the controlled movement of structures and systems while maintaining their integrity and functionality. Their proper design, material selection, installation, and maintenance are crucial for their effectiveness and the overall performance of the systems in which they are employed.