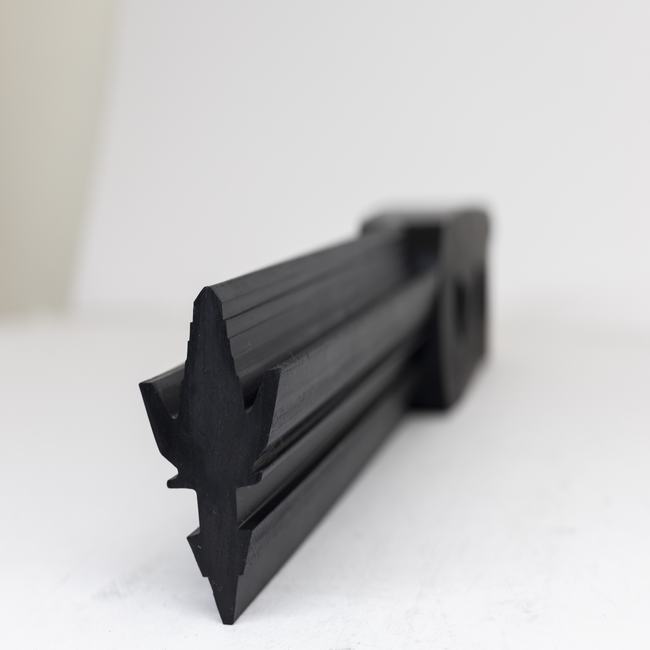

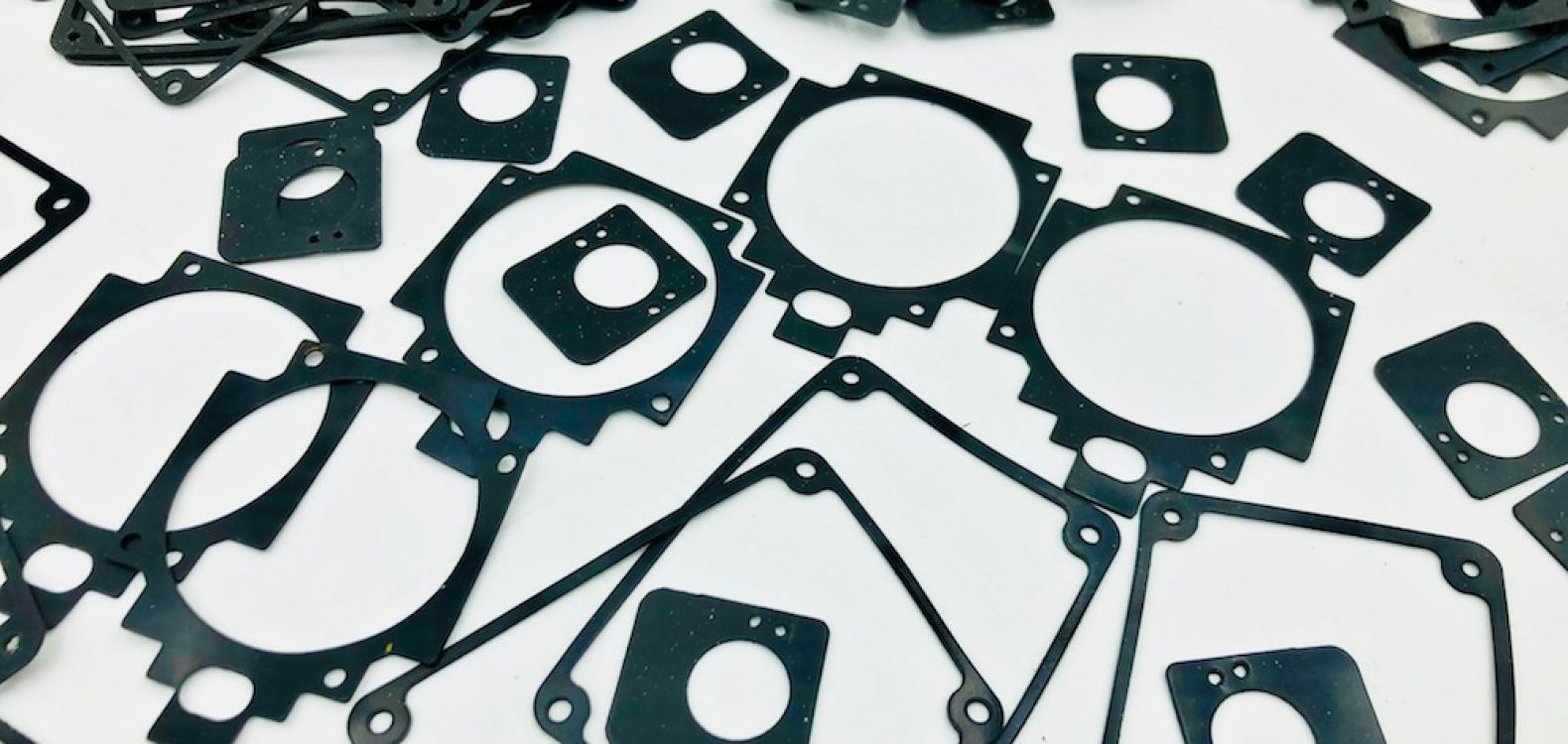

EPDM (Ethylene Propylene Diene Monomer) rubber gaskets are a type of sealing component made from EPDM rubber, which is a synthetic elastomer known for its excellent weather resistance, temperature resistance, and chemical resistance. EPDM rubber gaskets are widely used in various industries and applications due to their exceptional sealing properties and durability. Here are some key features and applications of EPDM rubber gaskets:

Key Features of EPDM Rubber Gaskets:

- Weather Resistance: EPDM rubber is highly resistant to weathering, UV radiation, ozone, and extreme temperatures, making it suitable for outdoor and exposed applications.

- Chemical Resistance: EPDM rubber exhibits good resistance to a wide range of chemicals, acids, and alkalis, making it compatible with various fluids and substances.

- Temperature Resistance: EPDM rubber can withstand both high and low temperatures, making it suitable for applications where temperature fluctuations are common.

- Excellent Sealing Properties: EPDM rubber gaskets provide effective sealing against air, water, moisture, and dust. They create a reliable and watertight seal in various conditions.

- Flexibility and Elasticity: EPDM rubber is flexible and elastic, allowing it to conform to irregular surfaces and maintain a tight seal even under compression.

- Longevity: EPDM rubber gaskets are known for their durability and long service life, even in challenging environments.

Applications of EPDM Rubber Gaskets:

- Automotive Industry: EPDM rubber gaskets are used in automotive applications, including sealing engine components, windows, doors, and hoods, to provide weatherproofing and noise insulation.

- Construction Industry: EPDM rubber gaskets are employed in construction for sealing doors, windows, roofing, and curtain wall systems to prevent air and water infiltration.

- HVAC (Heating, Ventilation, and Air Conditioning): EPDM rubber gaskets are used in HVAC systems to create airtight seals in ductwork, air handling units, and ventilation components.

- Electrical and Electronics: In electrical enclosures and electronic devices, EPDM rubber gaskets provide protection against moisture, dust, and environmental contaminants.

- Marine Industry: EPDM rubber gaskets are used in boats and ships for sealing hatches, ports, windows, and access panels, ensuring watertight integrity.

- Aerospace: EPDM rubber gaskets are used in aircraft components, such as doors and windows, to provide reliable sealing in demanding aerospace environments.

- Medical Devices: EPDM rubber gaskets are used in medical equipment and devices where resistance to chemicals and sterilization is essential.

- Food and Beverage Industry: EPDM rubber gaskets are employed in food processing equipment and beverage dispensing systems to maintain hygiene and prevent contamination.

- Industrial Machinery: EPDM rubber gaskets are used in various industrial applications, including sealing pumps, valves, and tanks.

Proper selection of EPDM rubber gaskets is crucial to ensure they meet the specific requirements of the application, including factors such as temperature range, chemical exposure, and compression requirements. Manufacturers’ guidelines and recommendations should be followed for optimal performance and longevity of EPDM rubber gaskets.