EPDM (Ethylene Propylene Diene Monomer) rubber seals are widely used in various industries and applications for their excellent sealing properties, durability, and resistance to environmental factors. EPDM rubber is known for its ability to withstand exposure to weather, temperature extremes, UV radiation, ozone, and a wide range of chemicals. EPDM rubber seals provide effective sealing against air, water, moisture, dust, and contaminants. Here are some common types and applications of EPDM rubber seals:

Common Types of EPDM Rubber Seals:

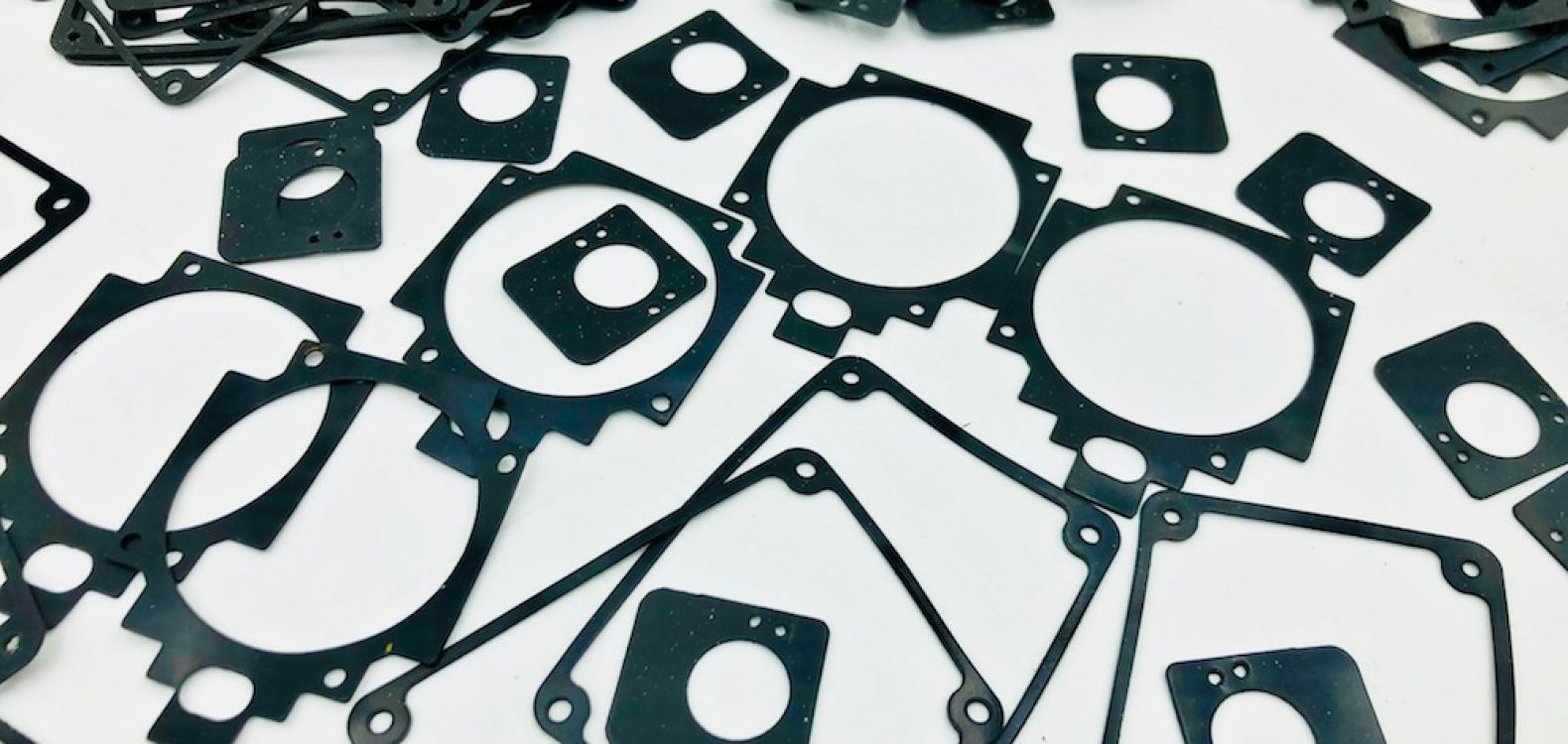

- Gaskets: EPDM rubber gaskets are used to create a seal between two mating surfaces, ensuring airtight and watertight connections. They are commonly used in flange joints, pipe connections, and machinery.

- O-Rings: EPDM O-rings are circular seals used in static and dynamic applications to prevent fluid or gas leakage. They are commonly found in hydraulic systems, pneumatic systems, and automotive engines.

- Weatherstripping: EPDM rubber weatherstripping is used in doors and windows to provide a weatherproof and airtight seal. It helps improve energy efficiency and reduce drafts in buildings.

- Hose and Tubing: EPDM rubber is often used to make flexible hoses and tubing, particularly for applications involving the transfer of fluids. These hoses can be found in automotive coolant systems, HVAC systems, and more.

- Profiles and Seals: EPDM rubber is used to create profiles and seals with specific shapes and dimensions to fit various applications, such as extruded rubber seals for automotive doors and windows.

Common Applications of EPDM Rubber Seals:

- Automotive Industry: EPDM rubber seals and gaskets are used in automotive applications, including door seals, window seals, gaskets, hoses, and engine components. They provide weatherproofing, noise insulation, and sealing functions.

- Construction Industry: EPDM rubber seals are employed in the construction of doors, windows, roofing, and HVAC systems to prevent air and water infiltration, improve insulation, and enhance energy efficiency.

- HVAC (Heating, Ventilation, and Air Conditioning): EPDM rubber gaskets and seals are used in HVAC systems to create airtight seals in ductwork, air handling units, and ventilation components.

- Electrical and Electronics: EPDM rubber seals are used to provide protection against moisture, dust, and environmental contaminants in electrical enclosures, control panels, and electronic devices.

- Marine Industry: EPDM rubber seals are used in boats and ships for sealing hatches, ports, windows, and access panels, ensuring watertight integrity.

- Aerospace: In the aerospace industry, EPDM rubber seals are used in aircraft components, such as doors, windows, and access panels, to provide reliable sealing in demanding aerospace environments.

- Medical Devices: EPDM rubber seals are used in medical equipment and devices where chemical resistance and sterilization compatibility are essential.

- Food and Beverage Industry: EPDM rubber seals are employed in food processing equipment, beverage dispensing systems, and pharmaceutical applications to maintain hygiene and prevent contamination.

- Industrial Machinery: EPDM rubber seals are used in various industrial applications, including sealing pumps, valves, tanks, and hydraulic systems.

Proper selection and installation of EPDM rubber seals are crucial to ensure they meet the specific requirements of the application, including factors such as temperature range, chemical exposure, and compression requirements. Manufacturers’ guidelines and recommendations should be followed for optimal performance and longevity of EPDM rubber seals.